The French selection of cheeses was great, a good mix of hard and soft cheeses delivered in excellent condition. What a shame the delivery company didn’t have the same high standards , delivery a day early, parcel left on the front doorstep in full sun not in the safe place specified. Just as well a photo was sent so we could ask a neighbour to retrieve the parcel and keep until our return 24 hours later!

Daniel ensured that our cheese order arrived at the requested date and time for our office event. The cheeses were packaged and wrapped perfectly, and the hard cheeses were already pre-cut for us as I had explained that we do not have a cheese knife or any sharp knives in our office. Daniel helped us with the cheese selection and with placing the order and provided helpful descriptions of the cheeses, so that I could describe the cheeses to my colleagues and know what to pair with them. He left a professional letter with the cheeses explaining why he had substituted one of the cheeses to ensure we received the best quality possible. This was good initiative and I appreciate this.

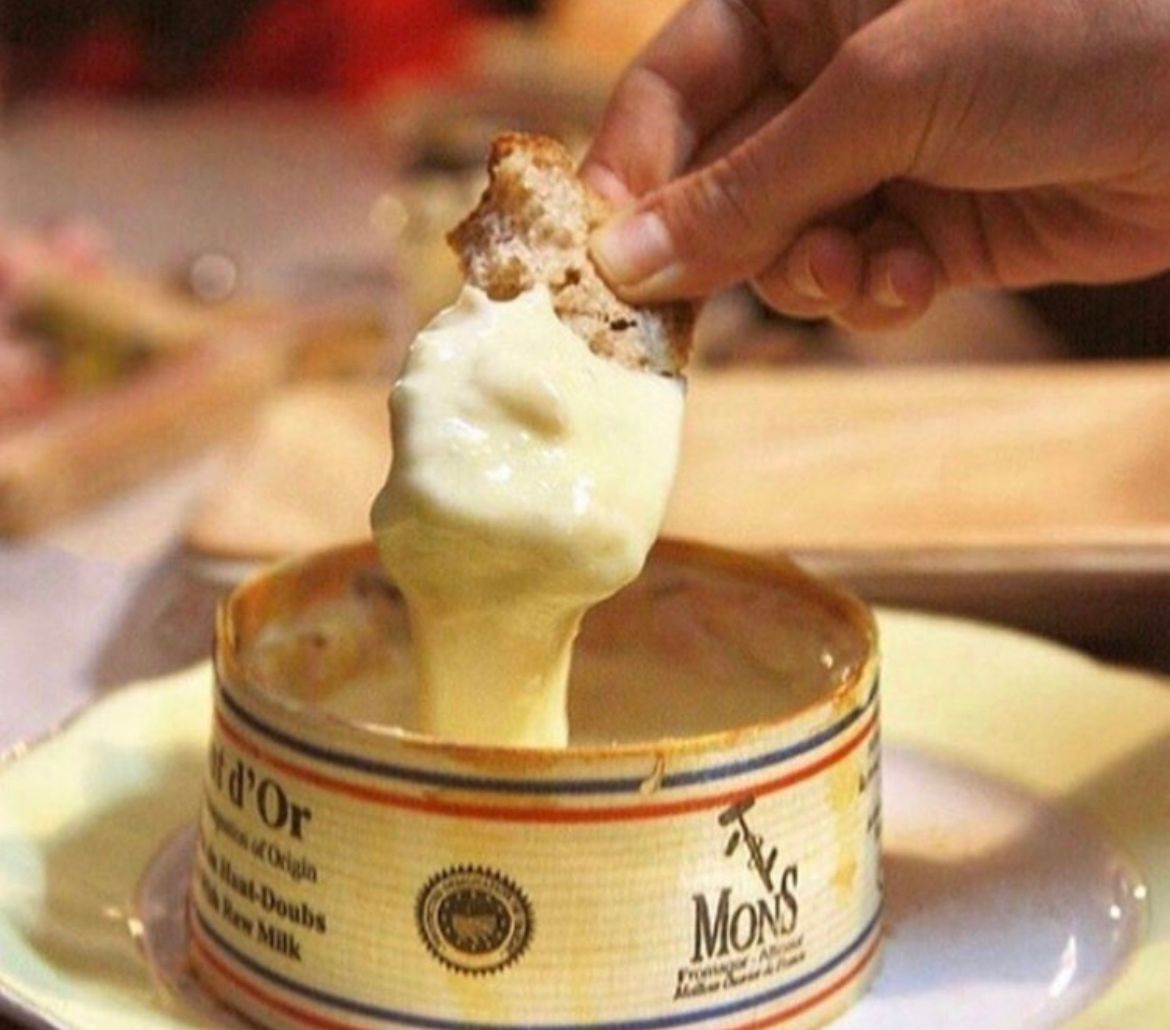

I have eaten this cheese is summer and winter and can appreciate the difference. there's a tendency for the non-expert to think the livestock eat the same thing, they produce the same milk and it makes a static type of cheese that you buy in the supermarkets. Geting to know cheeses through Mons shows they are as affected by the seasons and climate changes as wines or coffee are. I love the non-traditional format and the clean, slightly sharp flavour of the winter cheese, especially spread over a black damsal or beetroot biscuit. Very satisfying.

Everything was first class - from ordering online to collection. We always have a substantial cheeseboard over the holidays and Mons never disappoints! Lovely staff too.